Cold chain practices and standards: all you need to know

The control and monitoring of temperatures throughout the cold chain are very important issues with regard to the quality of goods. In order to ensure that food products and products from the pharmaceutical industry are kept at adequate temperatures and that these temperatures are recorded for continuous control purposes, a number of standards must be met.

European regulations

European regulations require, among other things, the use of recorders that comply with the regulations, which must be regularly checked (sensor calibration). These two aspects related to the traceability of the cold chain are the subject of standards called respectively EN12830 for the recorders and EN13486 for their verification.

The text of the EN12830 standard gives an example of the fields of activity identified: “Examples of goods that are sensitive to transport, storage and distribution temperatures between -80 °C and +85 °C are refrigerated, frozen and deep-frozen goods, ice cream, fresh and hot food, pharmaceuticals, blood, organs, chemicals, biological materials, electronic and mechanical devices, flowers, plants, bulbs, raw materials and liquids, animals, works of art and furniture. »

Focus

Within this regulation, the application scope is extensive. However, our specific focus lies on two significant sectors within transport and logistics:

- The storage and transportation of perishable goods requiring chilled, frozen, or deep-frozen conditions.

- The storage and transportation of medical products, including pharmaceuticals, blood products, organs, and medical samples.

In a context of globalization, the storage, transport and distribution of heat-sensitive products are subject to different regulations depending on the country. We will focus on the regulations on the European territory. There are many professions that have to comply with the regulations on cold chain traceability and you must make sure of the standards applicable to your branch of activity.

Advantage of open system

To ensure data security and integrity through an open system the hardware used must comply and the application must ensure the tracebility of the original data.

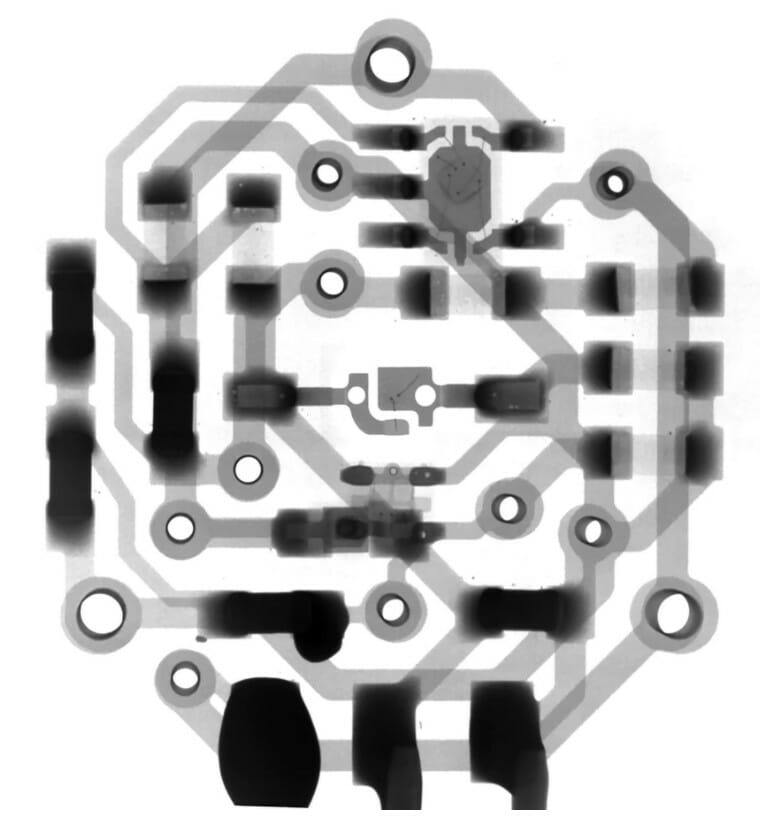

The temperature sensors itself are designed to meet the security and integrity requirements imposed by the standard. (EN12830 for recorders)

In some cases compliance with the standard is more difficult to achieve, as it requires that this be handled at the sensor level, which has limited computing resources. However, this way of doing things allows manufacturers to remain open to any independent system, while ensuring compliance with the EN12830 standard.

Hardware conformity is ensured by manufacturer certification and supported by independent accredited laboratories. EN13486 is for their verification of sensors.

Working with open systems ensures independency from supplier applications, as well as it ensures the flexibility to operate the best sensors for the job. An open platform will allow you to integrate all sensor recorders in one solution.

“European regulations require, the use of recorders that comply with the regulations, which must be regularly calibrated.

Perishable goods

The definition of the temperature accuracy you need to meet depends on your industry and your requirements. For example for the transport of perishable goods your recorder must be accurate to + or – 2°C. It must therefore be class 2 or better (Class 1 for example).

Pharma & Blood

For transport of pharmaceutical and blood products the recorder temperature class requested and frequently class 1 (+ or – 1°C accuracy) in the negative temperature ranges and class 0.5 (+ or – 0.5°C accuracy) in the positive ranges.

Safe and reliable readings

Use sensors complying with standards to secure goods and ensure cold chain continuity to minize the risk of audit failure and goods being damaged by not complying with cold chain requirements.

Read more about sensor monitoring

On our website you can read more about sensor monitoring here:

https://stra.com/en/sensor-monitor-iot/

Ready for a (non-)binding meeting

We would like to talk to you about which (standard) solutions we can assist you with. We offer you many years of experience and insights into do’s and don’ts.